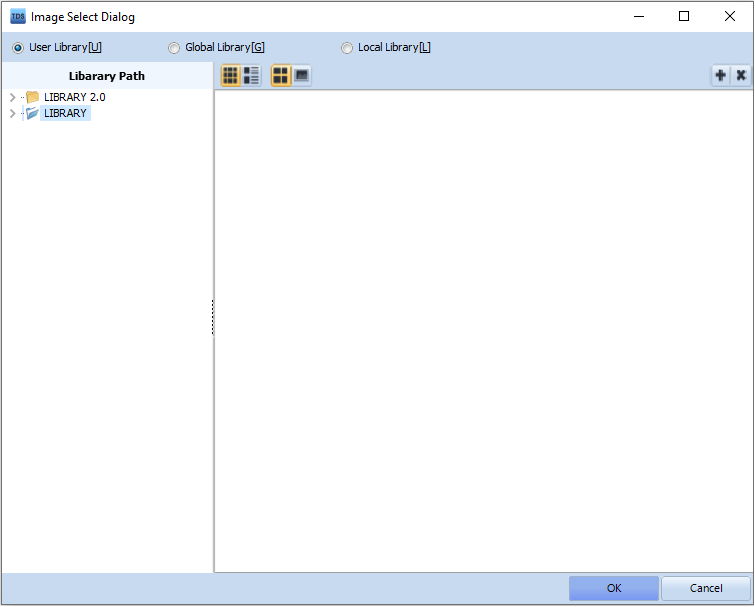

The [User Library] is the default image library provided in TDS.

It is automatically added during the installation of TOP Design Studio and is stored in the following directory:

C:\Program Files (x86)\M2I Corp\TOP Design Studio\Library

If the files are missing in the directory or the library images do not appear as shown above, the following causes should be checked:

[Possible Causes]

1. PC Access Restriction: The folder may be inaccessible due to permission limitations.

2. Firewall or Antivirus Blocking: The files may be blocked by a firewall or antivirus program.

[Solution]

-. Ensure that access permissions are granted to the library folder.

-. Temporarily disable the firewall or antivirus program, log in with an administrator account, and reinstall TOP Design Studio with Run as Administrator.

-. For detailed instructions, refer to the guide: [R Series] How to Reinstall TOP Design Studio in the FAQ.